Product Description

The Silver Refining Machine is an efficient device designed specifically for the purification and recovery of silver. As a professional supplier of Silver Refining Machines, we offer high-quality machines to ensure that customers have the best experience in the sale and use of Silver Refining Machines.

Raw Material

The Silver Refining Machine primarily uses low-purity silver materials as raw materials, ensuring the quality of the final product. The raw materials we select undergo strict screening to meet industry standards.

Silver Ingot Low Purity

Crude Silver Low Purity

Silver Jewelry Low Purity

Final Product

After processing with the Silver Refining Machine, customers will obtain high-purity silver suitable for various industrial and commercial applications. Our Silver Refining Machine effectively removes impurities, ensuring the quality and purity of the final product.

Silver Ingot High Purity

Crude Silver High Purity

Silver Jewelry High Purity

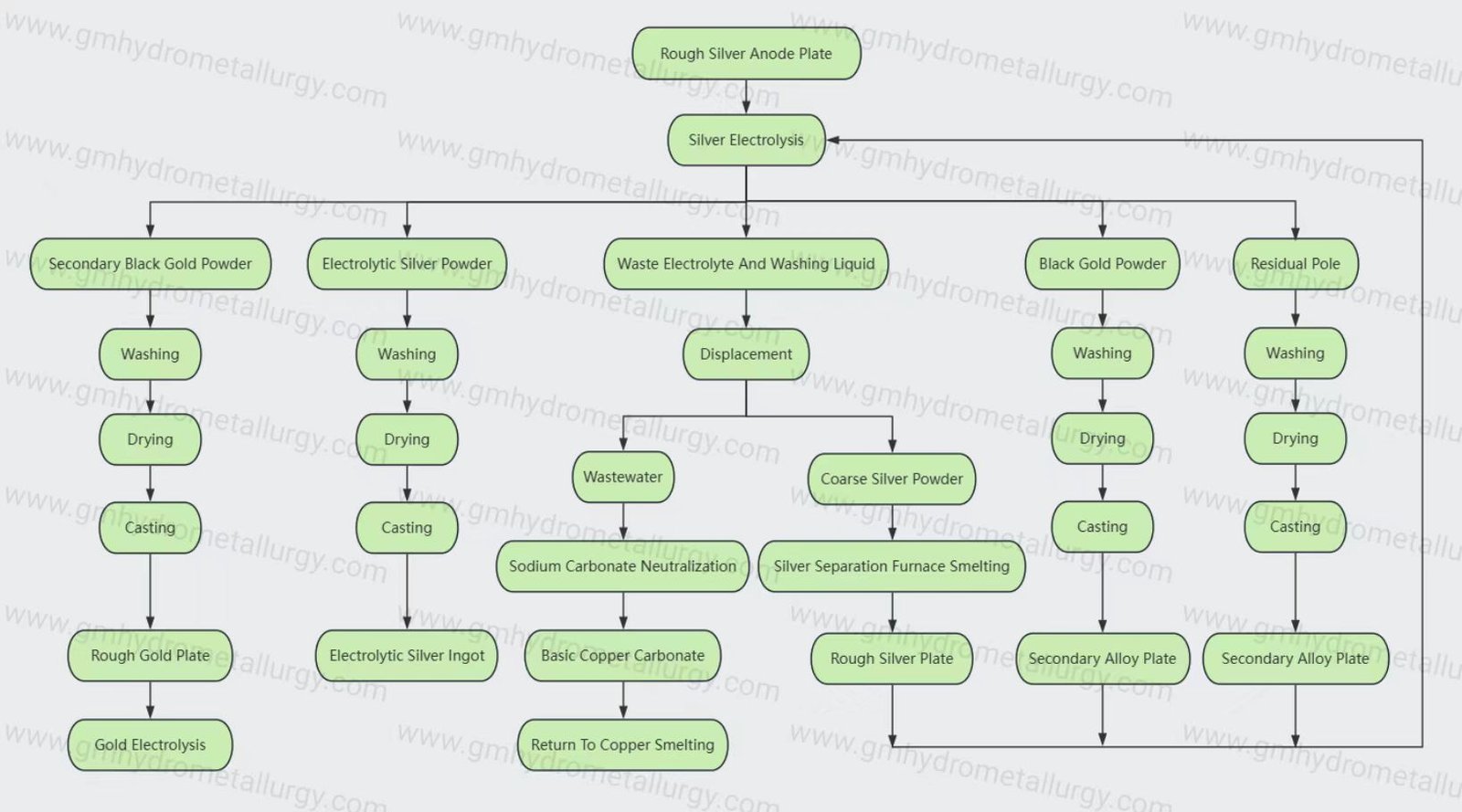

Flow Chart

The raw materials can be processed through the Silver refining machine process to produce crude gold plates, silver ingots, basic copper carbonate, crude silver plates, and secondary alloy plates.

1. Secondary black gold powder: After washing, drying, and smelting, crude gold plates can be produced, which can be sent to gold refining equipment.

2. Electrolytic silver powder: Electrolytic silver ingots can be produced through washing, drying, and smelting.

3. Waste electrolyte and washing liquid: Through copper replacement, waste liquid and crude silver powder are obtained respectively. The waste liquid is neutralized with sodium carbonate to produce basic copper carbonate, which can be sent to copper refining equipment. The crude silver powder is smelted in a silver separation furnace to produce crude silver plates.

4. Primary black gold powder and residual pole: After washing, drying, and smelting, secondary alloy plates can be produced.

Technical Parameter

Silver Refining Machine Technical Parameters

Working voltage can be customized, and if you have other requrement and want to know more details, please contact us.(The data in this table are for reference only)

| Model | Capacity kg/day | Power/kw | Size(Length*Width*Height) |

| SER-20 | 20kg | 5 | 1500*700*1850 |

| SER-50 | 20-50kg | 10 | 1600*800*1900 |

| SER-100 | 50-100kg | 15 | 570*840*1200 |

| SER-200 | 100-200kg | 25 | 1200*840*1300 |

| SER-300 | 200-300kg | 39 | 1930*840*1300 |